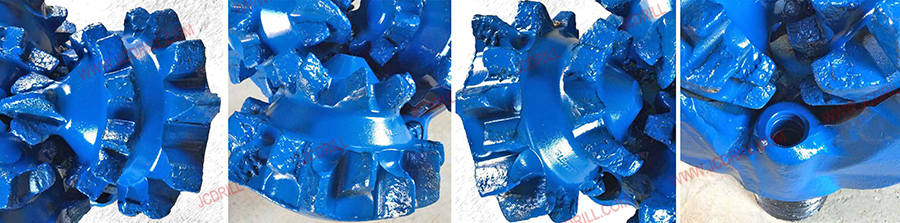

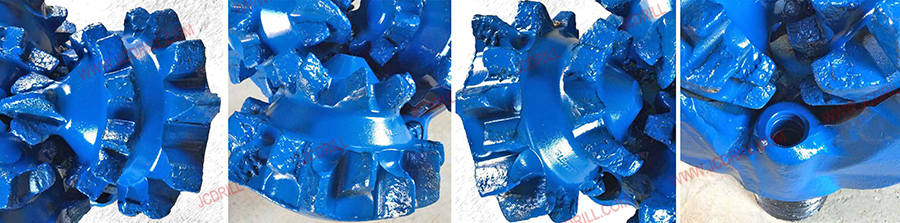

The Advantages of Tricone Drill Bits

1. High temperature heat treatment forged alloy steel . 2. Carbide teeth with high strength and toughness work more efficiently

TCI bits 1,Soft formations(417,437,517,537) Features large chisel-shaped inserts to provide the highest penetration rate in the softest formations such as shales, clays, limestone and sands. 2,Soft to medium formations(617,637) Designed to drill effectively in formations such as hard limestone, dolomite, hard sands, and other formations with hard cherty. 3,Medium to hard formations(737) For extremely hard formations such as chert, granite, flint, and taconite. Features short, closely-spaced inserts to ensure maximum penetration rate and wear resistance Milled tooth bits 1,Soft formations(114-117) These bits are designed to drill the softest formations such as soft shales,red beds, and clays, with high durability and maximum penetration rates. 2,Soft to medium formations(121,124,126,134,136,137) These bits are designed to drill formations such as shales, medium soft limestone, Medium sandstone and other formations with intermittent hard streaks. 3,Medium to hard formations(213,214,215,217) These bits are designed to drill formations such as hard sandstone, dolomite, and broken formations with hard cherty streaks Main features 1. Cutting Structure of this type sealed and non-sealed tci tricone bits : The wear-resistance of teeth is enhanced with premium tungsten carbide hard facing on the tooth surfaces for steel tooth bit. 2. Gauge Structure of this type tci tricone rock bits: Multiple gauge protection with gauge trimmers on the heel and gauge inserts on the gauge surface of the cone, tungsten carbide inserts and hard facing on the shirttail increases gauge holding capability and bearing life. 3. Bearing Structure of this type tci tricone rock bits : High precision roller bearing with two thrust faces. Ball locks the cone. Thrust faces hard face with wear resistant alloy. Abrasion resistance and seizure resistance of the bearing are improved. Table of classification of formation hardness and bit selection 3. Tooth palm lip hard welding surface with hard alloy ,Effectively prevent the drill bit wear and tear work

4. Head OD protection to effectively reduce head wear in abrasive formation and extend bit work 5.Directional jet enlarges lateral flow area and helpful bottom hole cleaning and increase of ROP 6. Lubricating system protection of bearing and seal system of bit extend bit work life 7. API REG Connection 8.Rubber sealed and metal sealed bearing

| Roller cone bit | IADC code of diamond bit | Formation description | Rock type | Compressive strength (Mpa) | ROP(m/h) |

| IADC code | |||||

| 111/124 | M/S112~M/S223 | Very soft:sticky soft formation with low compressive strength. | Clay Siltstone sandstone | <25 | >20 |

| 116/137 | M/S222~M/S323 | Soft:soft formation with low compressive strength and high drillability. | Clay rock Marl Lignite sandstone | 25~50 | 10~20 |

| 417/527 | M/S323~M/S433 | Medium soft:soft to medium formation with low compressive strength and steak. | Clay rock Marl Lignite Sandstone Siltstone Anhydrite Tuff | 50~75 | 5~15 |

| 517/537 | M322~M443 | Medium:medium to hard formation with high compressive strength and thin abrasive streak. | Mudstone Dark rock shale | 75~100 | 2~6 |

| 537/617 | M422~M444 | Medium hard:hard and dense formation with high compressive strength and medium abrasiveness. | Dark rock Hard shale Anhydrite Sandstone Dolomite | 100~200 | 1.5~3 |

IADC CODE SELECTION

IADC CODE SELECTION | IADC | WOB | RPM | Application |

| (KN/mm) | (r/min) | ||

| 111/114/115 | 0.3-0.75 | 200-80 | very soft formations with low compressive strength and high drill ability, like clay, mudstone, chalk |

| 116/117 | 0.35-0.8 | 150-80 | very soft formations with low compressive strength and high drill ability, like clay, mudstone, chalk |

| 121 | 0.3-0.85 | 200-80 | soft formations with low compressive strength and high drill ability, like mudstone, gypsum, salt, soft limestone |

| 124/125 | 180-60 | ||

| 131 | 0.3-0.95 | 180-80 | soft to medium formations with low compressive strength, like medium, soft shake, medium soft limestone, medium soft sandstone, medium formation with harder and abrasive interbeds |

| 136/137 | 0.35-1.0 | 120-60 | |

| 211/241 | 0.3-0.95 | 180-80 | medium formations with high compressive strength, like medium, soft shake, hard gypsum, medium soft limestone, medium soft sandstone, soft formation with harder interbeds. |

| 216/217 | 0.4-1.0 | 100-60 | |

| 246/247 | 0.4-1.0 | 80-50 | medium hard formation with high compressive strength, like hard shale, limestone, sandstone, dolomite |

| 321 | 0.4-1.0 | 150-70 | medium abrasive formations, like abrasive shale, limestone, sandstone, dolomite, hard gypsum, marble |

| 324 | 0.4-1.0 | 120-50 | |

| 437/447/435 | 0.35-0.9 | 240-70 | very soft formations with low compressive strength and high drill ability, like clay, mudstone, chalk, gypsum, salt, soft limestone |

| 517/527/515 | 0.35-1.0 | 220-60 | soft formations with low compressive strength and high drill ability, like mudstone, gypsum, salt, soft limestone |

| 537/547/535 | 0.45-1.0 | 220-50 | soft to medium formations with low compressive strength, like medium, soft shake, medium soft limestone, medium soft sandstone, medium formation with harder and abrasive interbeds |

| 617/615 | 0.45-1.1 | 200-50 | medium hard formation with high compressive strength, like hard shale, limestone, sandstone, dolomite |

| 637/635 | 0.5-1.1 | 180-40 | hard formation with high compressive strength, like limestone, sandstone, dolomite, hard gypsum, marble |

| Note: Above limits of WOB and RRPM should not be used simultaneously | |||

| Minimum Order Quantity | N/A |

| Price | |

| Packaging Details | Standard Export Delivery Package |

| Delivery Time | 7days |

| Payment Terms | T/T |

| Supply Ability | Based on Detailed Order |